Towing Wire Protector

Towing wire protector is a device designed to protect the towline. It’s typically made of abrasion – and corrosion – resistant polyurethane elastomer material. This protector reduces the friction between the cable and various object surfaces. It prevents the cable from suffering damage due to abrasion, corrosion, or extrusion, thus extending the cable’s service life.

The polyurethane cable protector is crucial during cable towing operations, ensuring the safety and stability of the process.

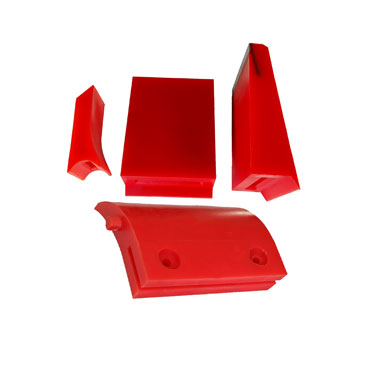

Polyurethane Towing Wire Protector

Advantage of Towing Wire Protector

- Manufactured with high-strength, abrasion-resistant polyurethane elastomers;

- Enhanced towline protection and safety;

- Excellent abrasion resistance and resistance to salt water, chemicals and acids and alkalis;

- Good impact resistance for kink and twist protection;

- Easy installation and removal;

- Customizable;

Application of Towing Sleeves and Towing Shoes

- 1. Ship Transportation and Towing

- 2. Marine scientific research

- 3. Offshore oil and gas industry

- 4. Fisheries

Custom Polyurethane Marine Towing Wire Rope Protector

- Product Specifications

- Gallery

Towing sleeves are designed with a one-piece construction and a round section. They can wrap tightly around the towing cable, resisting abrasion, corrosion, and pressure. These sleeves minimize cable wear and tear in scenarios such as boat towing and equipment hauling. We also offer customization services to provide you with tailor-made towing cable protection solutions.

Towing sleeves are designed with a one-piece construction and a round section. They can wrap tightly around the towing cable, resisting abrasion, corrosion, and pressure. These sleeves minimize cable wear and tear in scenarios such as boat towing and equipment hauling. We also offer customization services to provide you with tailor-made towing cable protection solutions.

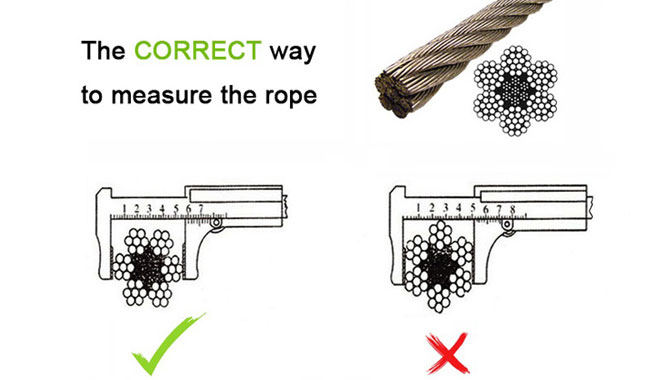

Specification of Polyurethane Towing Sleeve

| Items | Rope Diameter (mm) | Polyurethane Towing Sleeve Dimensions | ||

| ID.(mm) | OD.(mm) | Length | ||

| LS42 | 30~34 | 42 | 122 | 1~2M, or custom as your request. |

| LS48 | 36~40 | 48 | 122 | |

| LS58 | 42~50 | 58 | 188 | |

| LS68 | 52~60 | 68 | 188 | |

| LS78 | 62~68 | 78 | 188 | |

| LS84 | 70~76 | 84 | 188 | |

| LS100 | 78~90 | 100 | 215 | |

Specification of Cylindrical Polyurethane Towing Shoes

| Items | Rope Diameter (mm) | Bolt type Polyurethane Towing Shoes Dimensions | ||

| ID.(mm) | OD.(mm) | Length | ||

| LS-B42 | 30~34 | 42 | 122 | 1~2M, or custom as your request. |

| LS-B60 | 42~52 | 60 | 188 | |

| LS-B74 | 56~64 | 74 | 216 | |

| LS-B84 | 66~76 | 84 | 216 | |

| LS-B100 | 78~90 | 100 | 215 | |

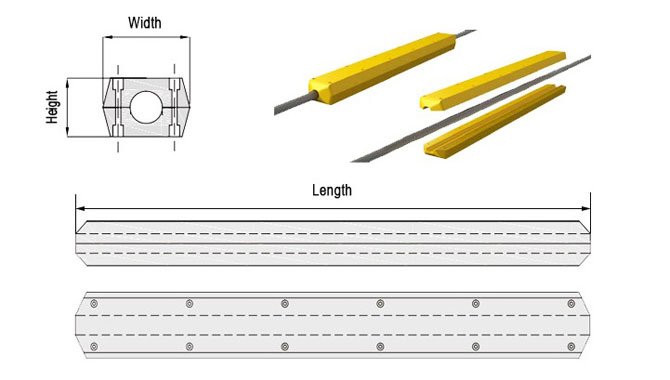

Specification of Rectangular Polyurethane Towing Shoes

| Items | Rope Diameter (mm) | Polyurethane Towing Shoes Dimensions | ||

| Width (mm) | Height(mm) | Length | ||

| LS42 | 42 | 230 | 155 | 1~2M, or custom as your request. |

| LS46 | 46 | 230 | 155 | |

| LS50 | 50 | 230 | 155 | |

| LS54 | 54 | 230 | 155 | |

| LS56 | 56 | 230 | 155 | |

| LS62 | 62 | 230 | 155 | |

| LS68 | 68 | 230 | 155 | |

| LS70 | 70 | 230 | 155 | |

| LS74 | 74 | 230 | 155 | |

| LS84 | 84 | 230 | 155 | |

| LS90 | 90 | 230 | 155 | |

Date Sheet of Polyurethane Elastomer Physical Property

| Polyurethane Prepolymer Properties | |

| % NCO | 4.3±0.2 |

| Appearance@20℃ | Transparent liquid |

| Viscosity@80℃/mPa·s | 800 |

| Melting condition,h/°C,20L | 8/80 |

| Curing agent | MOCA |

| Chain expansion coefficient(NH2/NCO) | 0.9 |

| Amount of curing agent(per 100 parts of prepolymer) | 12.5 |

| Temperature of prepolymer/°C | 80 |

| Curing agent temperature/°C | 110 |

| Recommended mold temperature/°C | 100 |

| Gel time/min(400g mix) | 6~8 |

| Demolding time/min(400g mix) | 30~40 |

| Post-curing,h@℃ | 16/100 |

| Hardness@20℃,Shore A | 85±2 |

| Hardness@20℃,Shore D | - |

| Tensile strength/MPa | 28.6 |

| 100% constant tensile strength/MPa | 7.6 |

| 300% constant tensile strength/MPa | 11.2 |

| Elongation at break/% | 520 |

| Tear Strength/(Right Angle,KN/m) | 80 |

| Resilience/% | 32 |

| DIN roller abrasion/m㎡ | 162 |

Related Products

Polyurethane towing wire protectors Manuafacuter

Towline wire protectors, designed for harsh offshore environments, have superb abrasion and corrosion resistance, and are suitable for high-intensity operational scenarios such as deep-sea oil extraction and large ship towing. We can customize according to your cable diameter and structural requirements, to provide you with tailor-made towing cable protection solutions.

It is made of high performance polyurethane with excellent abrasion resistance, flexibility and corrosion resistance. This enables it to effectively protect and extend the service life of towing cables in complex marine environments.

We have a wide range of conventional sizes to choose from to suit different diameters of trailing steel cables. Meanwhile, we specialize in customized service, you only need to provide detailed dimensional requirements, we can produce a precise fit for you.

Under normal use and maintenance, the service life of the protector is about 2-3 years in a harsh offshore environment. However, the actual life expectancy may be affected by the frequency of use, harshness of the environment and other factors.

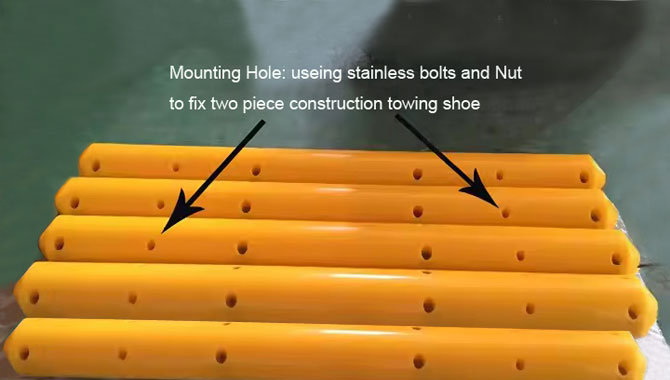

Installation is easy, useing stainless bolts and Nut to fix two piece construction towing shoe, which can be easily handled by crew members without complicated tools or specialized skills.

Compared with other materials, polyurethane material is lighter in weight, which will not add too much burden to the towing system. Meanwhile, it is more resistant to chemical corrosion, which can better resist the erosion of seawater, oil and so on, and it is flexible, which can tightly fit the steel cable.