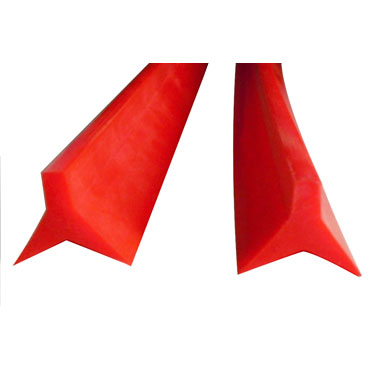

TPU Profiles

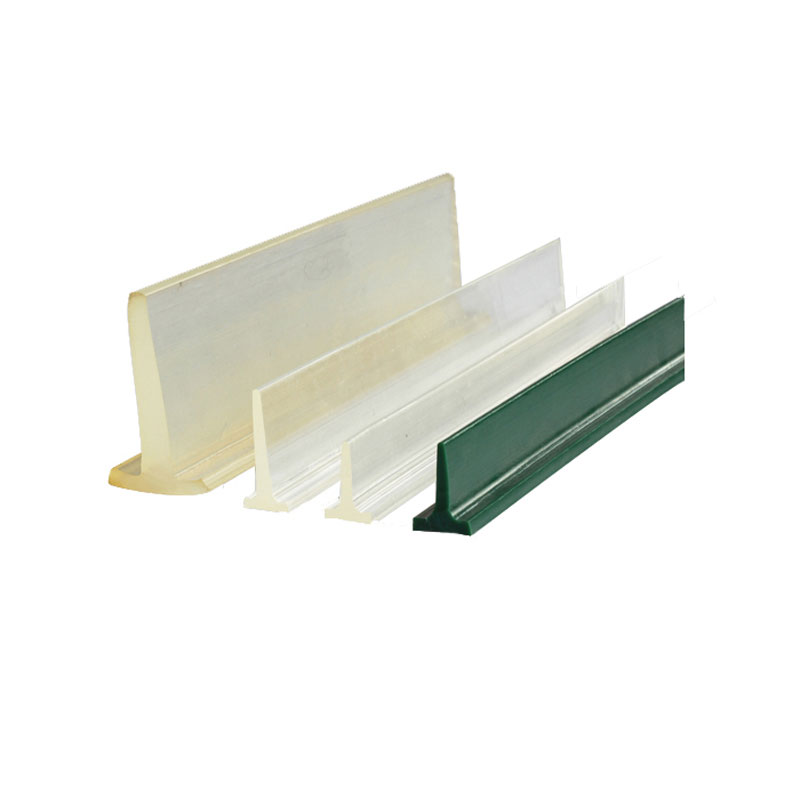

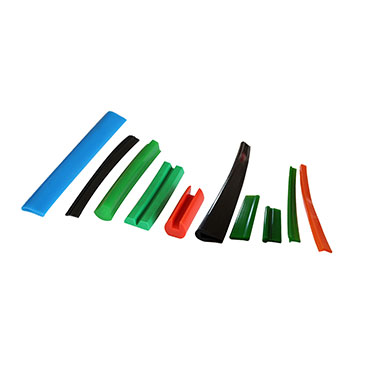

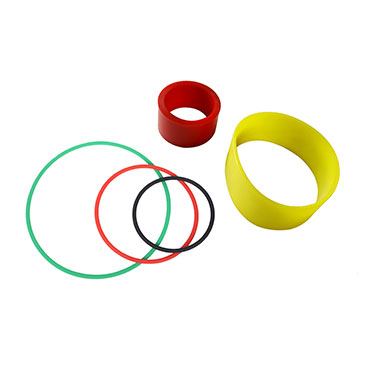

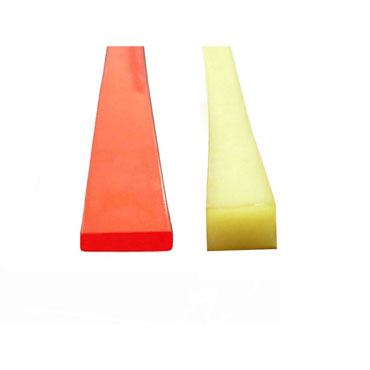

TPU profiles are custom-shaped components made from Thermoplastic Polyurethane (TPU). This material combines the benefits of rubber and plastic, offering high elasticity, wear resistance, oil resistance, and transparency.

During production, manufacturers heat TPU and force it into molds to create specific shapes. Afterward, they cool and cut the profiles to the required lengths. Thanks to its exceptional properties, TPU profiles suits a wide range of applications.

Thermoplastic polyurethane (TPU) Extrusions Profiles

Why Choose Our TPU Profiles

- Customizable to Your Needs

- High Durability

- Chemical & Abrasion Resistance

- UV & Weather Resistant

- Recyclable & Environmentally Friendly

Applications for TPU Polyurethane Profiles

- Automotive: Seals, gaskets, and wear-resistant parts.

- Industrial Machinery: Protective covers, wear strips, and conveyor guides.

- Material Handling: Belt guides, sealing solutions, and wear protection.

- Food & Pharmaceutical Industries: FDA-compliant profiles for conveyor systems, gaskets, and seals.

- Robotics & Automation: Used for robotic arms, sealing, and wear protection.

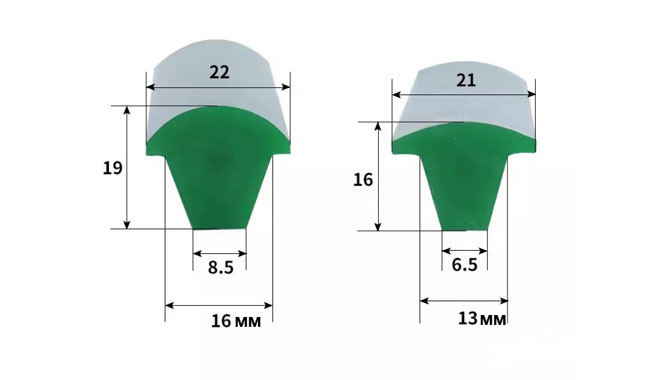

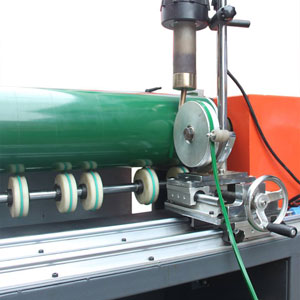

Conveyor Belt Guides- Polyurethane Plastic Molding Products

- Product Specifications

- Gallery

| Specification | Details |

| Material | Thermoplastic Polyurethane (TPU) – High-performance thermoplastic elastomer combining rubber and plastic. |

| Shape and Design | Custom Profiles: Available in round, square, U, T, and other custom shapes. |

| Length | Custom lengths or standard lengths based on application needs. |

| Cross-sectional Design | Customizable for seals, wear strips, gaskets, etc., to match exact needs. |

| Hardness | Typically ranges from 70 to 98 Shore A, with custom options for load-bearing or flexibility. |

| Tensile Strength | Range: 35 MPa to 80 MPa, suitable for high-stress and abrasion resistance applications. |

| Elongation at Break | 200% to 400%, offering flexibility and tear resistance. |

| Temperature Resistance | Operating Range: -40°C to 80°C (some grades can withstand up to 120°C). |

| Chemical Resistance | Resistant to oils, greases, alkalines, alcohols, UV, ozone, and chemical agents. |

| UV Resistance | Excellent UV stability, suitable for outdoor applications. |

| Ozone Resistance | Ideal for long-term outdoor exposure. |

| Applications | Sealing Profiles, Wear Strips, Protective Covers, Food & Medical applications. |

| Customization | Custom colors, surface textures, and reinforcements (fiberglass, steel, Kevlar) available. |

| Compliance | FDA Compliance (for food applications), ISO 9001 (quality control). |

| Advantages | High strength, durability, flexibility, and custom fit for specific industrial requirements. |

| Packaging and Delivery | Available in bulk or custom packaging based on order size. |

Related Products

Polyurethane TPU Extrusion Profiles Manufacturer in China

As a thermoplastic polyurethane elastic, TPU can be melted and reformed, making it more environmentally friendly than some other polymers. We can custom extrusion PU profiles in any shape, size, or hardness, making TPU profiles adaptable for varity of industries application.

TPU Profiles are made through the extrusion process, where TPU material is melted and formed into custom shapes. This ensures high precision, excellent dimensional consistency, and allows for customized profiles to suit various industrial applications.

TPU (Thermoplastic Polyurethane) offers superior abrasion resistance, elasticity, and flexibility compared to rubber and plastic. Unlike rubber, TPU has better wear resistance and is more durable, making it ideal for high-performance applications in harsh environments.

TPU Profiles provide excellent durability, flexibility, and chemical resistance, making them perfect for high-stress environments. They also offer UV resistance, ensuring long-term performance in outdoor and exposed applications, such as seals, gaskets, and wear-resistant strips.

TPU Profiles are highly resistant to UV radiation, ozone, and weathering, making them durable in outdoor environments. They are ideal for applications in exposed areas, such as conveyor systems, automotive parts, and construction machinery.

Yes, TPU Profiles can be manufactured in compliance with FDA regulations, making them suitable for food contact applications. Their non-toxic and chemical-resistant properties ensure that they can be used in food processing, packaging, and conveying systems.