Polyurethane Applications in the Automotive Industry

Polyurethane plays a vital role in automotive manufacturing, offering durability, flexibility, and abrasion resistance. It supports safe, efficient, and reliable vehicle operation in demanding environments.

Our urethane products reduce noise, absorb vibration, and protect critical systems, helping extend vehicle lifespan and minimize maintenance needs.

Why Choose Our Automotive Urethane Solutions

- Durability & Safety – Withstand heavy loads, high impact, and continuous motion in automotive applications.

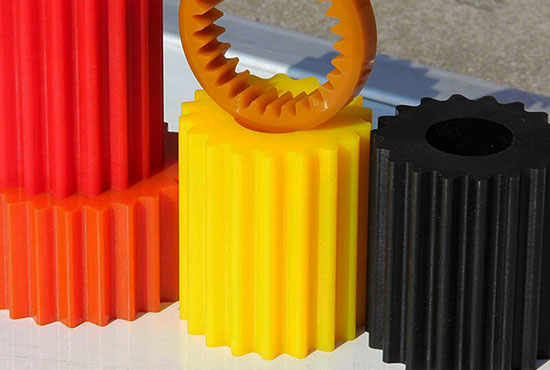

- Custom Design – Tailored hardness, shape, and color to meet OEM and aftermarket requirements.

- Efficiency & Cost Savings – Reduce wear and downtime, ensuring long-term reliability and lower operating costs.

Polyurethane Products for Automotive Applications

- Bushings & Mounts – Absorb shocks and vibration for smoother, quieter rides.

- Seals & Gaskets – Ensure leak prevention and system reliability in engines and transmissions.

- Wheels & Rollers – Provide wear resistance and long service life in assembly lines and automotive equipment.

- Protective Pads & Guards – Reduce part wear, enhance safety, and protect components under constant stress.

Industries & Scenarios in Automotive

- OEM Vehicle Manufacturing – Custom urethane parts ensure durability in high-volume production.

- Aftermarket Parts Replacement – Reliable replacement bushings, seals, and mounts improve vehicle safety and performance.

- Assembly Line Equipment – Urethane rollers and pads ensure smooth, efficient material handling during automotive production.

Benefits for Automotive Companies

- Extend the lifespan of vehicles and equipment.

- Improve safety, comfort, and performance.

- Lower operating and maintenance costs.

- Customize urethane components to exact OEM and aftermarket needs.

Learn More About Polyurethane in Other Industries

Send Inquiry