Urethane Casting

Urethane casting is a process where liquid polyurethane is poured into molds and cured to create high-performance molded parts. Unlike urethane injection molding, urethane casting allows greater flexibility in:

-

- Producing low volumes without costly tooling.

- Creating complex geometries and detailed designs.

- Customizing material formulations to match specific requirements.

Manufacturers often choose this process to produce rapid prototypes, functional testing parts, or short-run production with production-grade quality.

Our Urethane Casting Capabilities

- Custom Mold Design – Precision-engineered molds for unique parts.

- Material Options – Flexible polyurethane formulations from soft elastomers to rigid plastics.

- Low-Volume Runs – Cost-effective solutions for prototypes or small batches.

- Complex Part Production – Thin walls, internal features, and intricate geometries.

- Color & Additives – Custom colors, FDA-compliant materials, flame-retardant, or anti-static options.

- Overmolding – Urethane bonded to metals, plastics, or composites for hybrid parts.

Cast Urethane Molding Process

- Step 1 – Design & Mold Creation,CAD files and mold design, Molds made from aluminum or steel, urethane casting tooling is faster and lower-cost tooling than injection molds.

- Step 2 – Material Preparation, Mix liquid polyurethane, Adjust hardness, color, and properties Options: wear resistance, chemical resistance, FDA-grade, flame-retardant.

- Step 3 – Casting, Pour liquid urethane into mold, Controlled temperature and pressure.

- Step 4 – Curing, Material solidifies into final shape, Ensures precision and durability.

- Step 5 – Demolding & Finishing, Remove cured parts, Trim, machine, or surface-treat as needed.

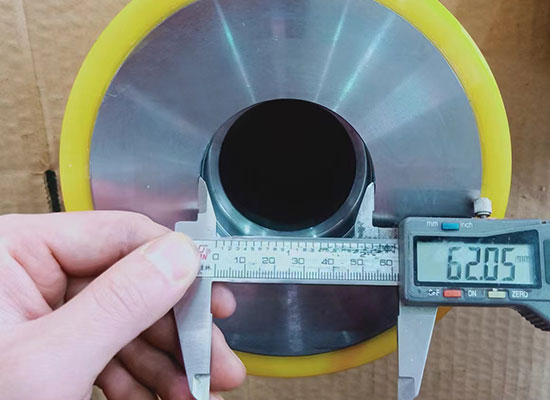

- Step 6 – Quality Control, Dimensional inspection, Hardness and performance testing, Guaranteed consistency and reliability.

Quality Control for Cast Urethane Parts

- Strict monitoring of temperature, pressure, and curing time.

- Prevention of defects like air bubbles, shrinkage, and deformation.

- Comprehensive testing for dimensions, hardness, wear, and bonding strength.

- Optimized production plans to ensure on-time delivery and consistent quality.

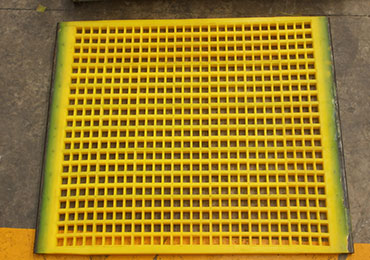

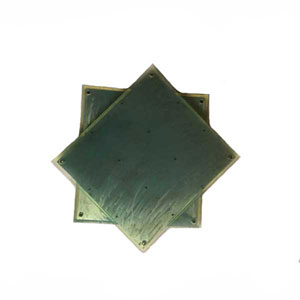

Cast Polyurethane Products Examples

Urethane Casting Services Support Diverse Industries

Cast Urethane Manufacturers – You Design It, We Produce It

As an experienced polyurethane molding manufacturer, we offering flexible, cost-effective solutions for custom polyurethane parts. This process is ideal for creating low- to medium-volume production runs, prototypes, and complex designs. With our advanced capabilities, we deliver parts that are durable, precise, and tailored to meet the performance needs of industries ranging from mining and automotive to industrial equipment and consumer products.

Looking for a partner in urethane casting? Request a Quote Today, and let us deliver durable, high-performance polyurethane components designed for your exact needs.

Poured polyurethane, also called casting polyurethane, is made by mixing liquid components and pouring them into a mold. After curing, it forms durable, high-performance parts.

- Urethane casting offers lower tooling costs compared to injection molding.

- Faster turnaround for prototypes and small runs.

- High level of design flexibility.

- Smooth surface finish with cosmetic quality.

- Strong wear resistance and chemical resistance.

- Cost-effective alternative to machining or injection molding for short runs.

Common applications include mining, material handling, automotive, industrial equipment, construction, packaging, and consumer products.

We manufacture rollers, wheels, liners, bumpers, seals, gaskets, and custom-molded components in a wide range of sizes and shapes.

Pouring polyurethane is best for low- to medium-volume runs, large parts, or complex designs. Injection molding is better for high-volume, high-precision production.

Yes. We can adjust hardness (durometer), color, size, and surface finish. Special formulations like FDA-compliant, anti-static, or flame-retardant grades are also available.