Urethane Injection Molding

Injection molded polyurethane, also called urethane injection molding, is a manufacturing process that melts solid TPU pellets and injects the flowable material into a precision mold. The mold shapes the material into durable, high-quality components. This process produces parts with tight tolerances, smooth surfaces, and precise dimensions. It works well for complex geometries, including thin walls, internal grooves, and intricate shapes.

Compared with cast urethane, injection-molded parts have higher stiffness, excellent tensile strength, and superior chemical and abrasion resistance. They withstand demanding industrial, automotive, aerospace, and consumer applications. This method delivers structural reliability and aesthetic quality, supporting both prototyping and high-volume production.

Our Urethane Injection Molding Capabilities

- Custom Mold Design – Tailored molds to meet your exact specifications.

- High Precision Production – Tight tolerances and consistent part quality.

- Material Flexibility – 75 -95 Shore A formulations for specific performance requirements.

- Insert & Overmolding – Bonding urethane to metals, plastics, or composites for enhanced strength.

- Low-Volume & High-Volume Runs – Ideal for prototypes, pilot runs, or mass production.

- Color & Formulation Options – Custom colors, anti-static, oil-resistant, or FDA-compliant grades.

- Cosmetic Quality – Smooth, flat surfaces often require minimal post-processing.

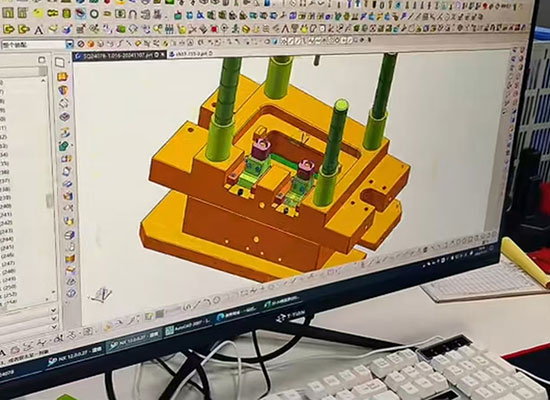

Injection Mold Design & Technology

Injection molds typically consist of top and bottom structures, sometimes with multiple parts. We perform precision machining on contact surfaces to ensure:- Tight closure of the mold.

- Prevention of material leakage.

- Dimensional accuracy of finished parts.

- Complete shape and excellent surface quality.

Materials & Technical Specifications

Our material options ensure urethane components perform reliably in diverse applications:- Hardness Range: Shore A 70–95.

- Temperature Resistance: –40°C to 80°C (higher temperature grades available).

- Abrasion Resistance: 3–5x better than rubber.

- Chemical Resistance: Oils, fuels, solvents, and corrosion.

- Structural Performance: High stiffness and tensile strength suitable for parts subjected to large external forces.

- Part Sizes: From small precision components to large molded parts.

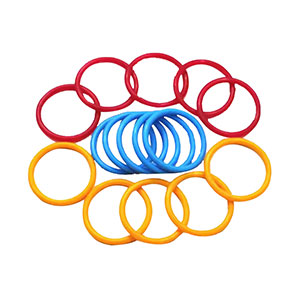

Cases of Injected Polyurethane Parts

Urethane Injection Molding Applications

Why Partner With Us?

As a trusted custom polyurethane molding manufacturer, we combine advanced urethane injection molding technology with engineering expertise to deliver reliable, high-performance components. Our solutions reduce downtime, improve operational efficiency, and are tailored to your exact application needs, from design support and prototyping to full-scale production.

Looking for a partner in urethane injection molding? Request a Quote Today and receive custom, high-performance polyurethane components designed for your project.

Quality Assurance

We maintain strict quality control throughout production:

- In-house inspection and testing.

- Dimensional and hardness verification.

- Mold performance and bonding tests.

- Compliance with customer and industry standards.

We can produce bushings, rollers, liners, gaskets, vibration-dampening components, structural parts, and more. The process handles thin walls, internal grooves, and intricate geometries.

We primarily use thermoplastic polyurethane (TPU) pellets, which are melted into a flowable state for molding. Various hardness grades and formulations are available to meet performance requirements.

Industries include automotive, aerospace, mining, industrial machinery, consumer goods, construction, marine, and food packaging, especially where durability, precision, and chemical resistance are critical.

Injection-molded parts have tight dimensional tolerances, excellent surface finish, and consistent performance, making them suitable for both functional and cosmetic applications.

Yes. The compact molecular structure and material selection provide high abrasion resistance, chemical resistance, and long service life in demanding environments.

Yes. We provide custom mold design, material selection guidance, and engineering support to create polyurethane components that meet your exact specifications.