V Groove Roller Wheels

V-Groove roller wheels made from polyurethane material with a V-shaped groove molded into the tread. This V-groove allows the wheel to roll precisely along a corresponding V-shaped track or angle iron, commonly used in industrial guiding systems.

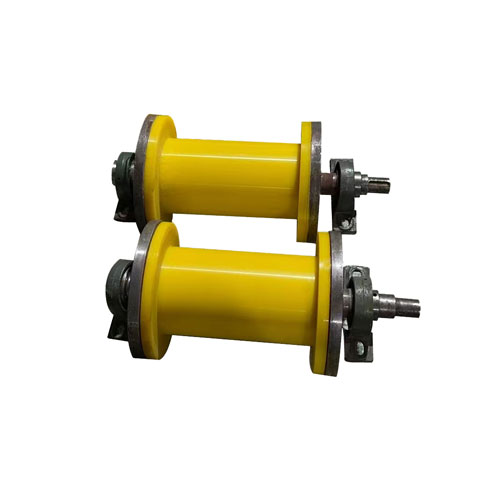

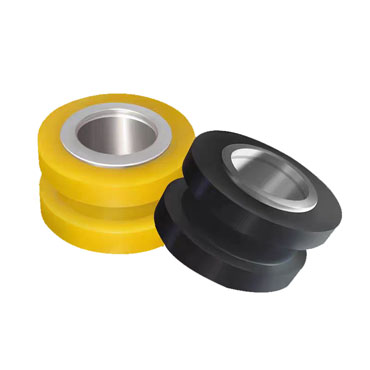

Polyurethane V Groove Roller Wheels

Why Choose Our Polyurethane V- Groove Roller Wheels?

- Customized Polyurethane Formulas: Tailored to your load, environment, and speed requirements.

- Precision Molded: Excellent concentricity and tracking performance.

- Integrated Bearings: Low-friction, high-load performance.

- Shock Absorbing: Protects cargo, floors, and systems.

- Durable and Quiet: Longer life span than rubber or steel with significantly less noise.

Applications of V- Groove Polyurethane Roller Wheels

- Automated Guided Vehicles (AGVs)

- Warehouse carts & conveyor systems

- CNC machines & robotic platforms

- Sliding gates & curtain tracks

- Factory mobile equipment and dollies

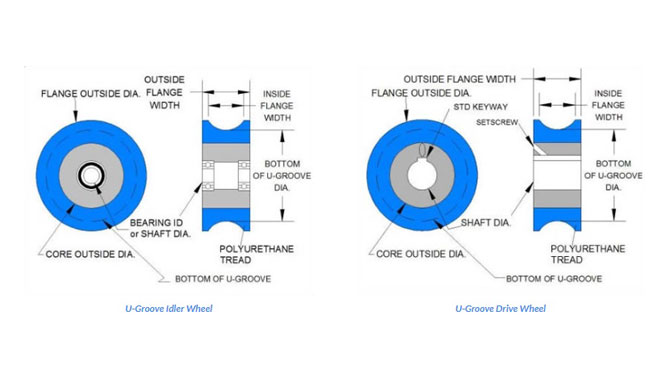

Custom Urethane V Groove Wheels (Bore, Keyway, Hub Variants)

- Product Specifications

- Gallery

Polyurethane V Groove Roller Wheels

| Specification | Details |

| Material | High-performance polyurethane (custom durometer options) |

| Hardness (Shore A/D) | 70A – 95A or 55D (customizable based on load & environment) |

| Core Material | Steel, aluminum, or plastic (custom options available) |

| Groove Angle | Standard 90° V-groove (custom 60°, 120°, or custom groove profiles on request) |

| Wheel Diameter | 50 mm – 300 mm (custom sizes available) |

| Load Capacity | Up to 2,000 kg per wheel (depending on size and core) |

| Bearing Type | Precision ball bearings, sealed bearings, or stainless-steel options |

| Temperature Range | -30°C to +80°C (with special formula up to 120°C) |

| Color | Red, yellow, blue, natural – customizable |

| Mounting Type | Plain bore, keyed bore, press-fit bearings, or integrated shaft |

| Track Compatibility | Steel V-track, angle iron, aluminum rail systems |

| Noise Level | Low-noise operation (ideal for indoor & clean environments) |

| Applications | AGV systems, automated gates, material handling carts, robotic rails, CNC |

| Customization | Groove width, angle, tread profile, durometer, and branding available |

Related Products

V Groove Roller Wheels -Polyurethane & Caster Solutions for Track Systems

As a professional manufacturer of polyurethane products, we specialize in customized V Groove Roller Wheels engineered for smooth, guided motion across V-tracks, angle iron, or pipe rails. Whether you're automating material handling, enhancing your AGV systems, or building track-guided carts.

our polyurethane V-groove and U-groove wheels provide excellent wear resistance, low noise, and load reliability. We offer both standard and fully customizable designs to meet your unique industrial or automation needs.

V Groove Roller Wheels are designed to run along V-shaped tracks or angle iron, commonly used in sliding gates, material handling carts, and industrial automation systems where guided linear motion is required.

Polyurethane offers superior wear resistance, lower noise, better shock absorption, and does not damage floors or tracks. It’s ideal for indoor use, high-speed systems, or applications that require a quieter, cleaner working environment.

Yes, we specialize in custom polyurethane molding and can tailor the wheel diameter, groove angle, tread hardness, bearing type, and core material according to your specific application needs.

Selection depends on your load, track type, operating speed, temperature, and environmental conditions. You can contact our engineering team for technical support and free selection guidance.

Lead times vary based on order quantity,custom-molded wheels typically require 15–20 working days. We ensure on-time delivery with quality assurance.