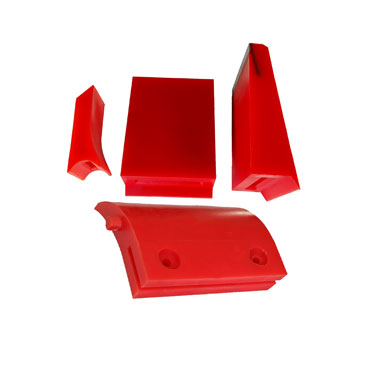

V-plough Scraper

V-plough scraper is a return-belt cleaning device installed before the tail pulley. Its V-shaped blade splits and deflects debris to both sides, protecting the belt, pulleys, and rollers. Unlike primary or secondary scrapers, it focuses on the belt’s underside for efficient carryback removal and material control.

V Plough Scraper for Return Conveyor Belt Cleaning

Key Benefits of Polyurethane V-Plough Scrapers

- High abrasion resistance against heavy and abrasive materials;

- Flexible PU blades prevent belt damage;

- Efficient carryback and debris removal;

- Long service life and lower maintenance costs;

- Adjustable, spring-loaded, and custom options for exact fit.

Industry Applications

- Mining conveyors;

- Cement plants;

- Aggregate & quarry operations;

- Power plants;

- Bulk material handling systems.

V-Type Plow Conveyor Belt Scraper for Return Belt Cleaning

- Product Specifications

- Gallery

| Specification | Options / Details | Notes |

| Material | Polyurethane (PU), Urethane, Optional Rubber | High abrasion resistance, flexible belt contact, long service life |

| Blade Type | Standard, Heavy-Duty, Replacement, Custom/OEM | Select based on conveyor load and material type |

| Length | 300–2000 mm (customizable) | Can be tailored to match conveyor width |

| Thickness | 6–25 mm | Depending on material, duty, and wear requirements |

| Hardness (Shore A) | 70–95 | Soft for flexible contact, hard for abrasive materials |

| Mounting Style | Bolt-on, Clamp-on, Custom | Compatible with primary/secondary or return-belt scrapers |

| Operating Temperature | -40°C to 80°C | High-temperature PU grades available |

| Applications | Mining, Quarrying, Cement, Bulk Handling, Power Plants | Aggressive carryback removal, reduced spillage |

| Replacement Compatibility | OEM or custom replacement | Ensures exact fit and performance restoration |

| Custom Options | Profile, length, hardness, mounting | Designed per customer drawings or sample molds |

Related Products

Custom & OEM V-Plough Scraper Manufacturing

We produce custom and OEM V-plough scrapers based on your conveyor specifications. Using drawings or samples, we tailor blade length, profile, hardness, and mounting for exact fit, reliable performance, and maximum return-belt protection in demanding industrial operations.

V‑plough scrapers are widely used in mining, cement, aggregate, bulk material handling, and power plants. They are essential where abrasive materials and heavy return belt carryback cause wear, spillage, or belt damage.

Polyurethane V‑plough scraper blades offer higher abrasion resistance than rubber and gentler belt contact than metal. This combination reduces belt wear, extends blade life, and improves cleaning performance in heavy‑duty conditions.

Consider the belt width, material abrasiveness, load, return belt speed, and spillage level. Heavy‑duty or wear‑resistant polyurethane blades are ideal for abrasive materials, while adjustable or spring‑loaded systems work well where belt tension varies.

Yes. Many V‑plough scrapers feature replaceable blades. Replacement blades (e.g., polyurethane V‑plough scraper blades) allow maintenance teams to restore cleaning performance without changing the complete frame.

Common mounting options include bolt‑on and clamp‑on systems. Custom mounting designs are also available to fit existing frames or non‑standard conveyor structures.